Design not appearing

▶ Description of the problem

You can see a faded version of your stencil on the screen but it can't let ink pass through.

▶ Possible origins

This is a clear indicator of overexposition. There are several possible reasons for that

- The exposure time was too long.

- The exposure lamp was to close to the screen.

- Light passed underneath the transparent stencil during exposure.

- The screen was received some light while drying.

▶ Solution

1. It might be because the screen received some light while drying, or you waited to long before putting it in a dark place to dry.

After coating the screen, it should immediatly be put in total darkness to dry for a few hours (usually 4 to 12 hours, but it can go up to 24 hours depending on the conditions).

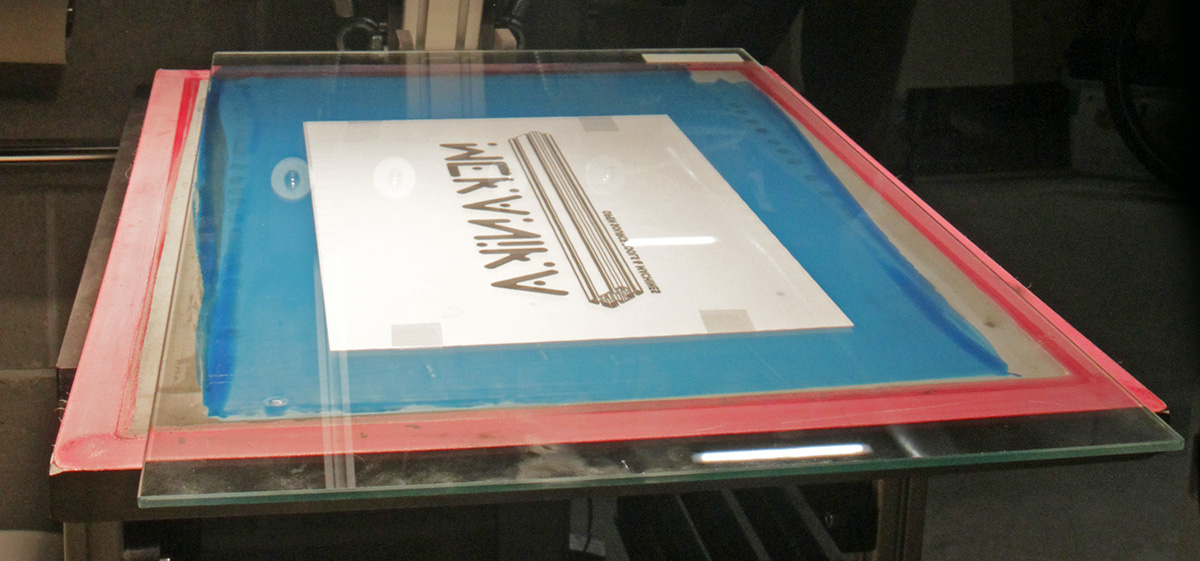

2. Second possibility, the transparent with your stencil printed on it was not completely flat on the screen during exposure. Some light from the lamp might have passed on the sides and or bounced underneath and ended up exposing the coating at places you didn't want it to.

To solve that, put a transparent glass or plexiglass (acrylic) panel on the transparent sheet to press it against the screen during exposure. It will ensure no light can pass on the sides.

3. You can also verify the distance from the exposure lamp to the screen.

With Mekanika's exposure kit, it should be around 60 cm.

5. Last, make sure to follow the exposure's timing instruction precisely, or even better: follow this tutorial to do an exposure calculation to get the prefect timing for your own setup!