Z axis can't move upwards - Spindle only goes down

▶ Description of the problem

When pressing Z arrows on your key pad or screen, the Z axis only goes down but can never go upwards.

▶ Possible origins

There are many different possibilities, it can be hardware related (something blocks the axis) or software related (the computer doesn't want to go up because he thinks it is not supposed to).

▶ Solution

Please answer the questions below to resolve your issue

▶ Let's begin:

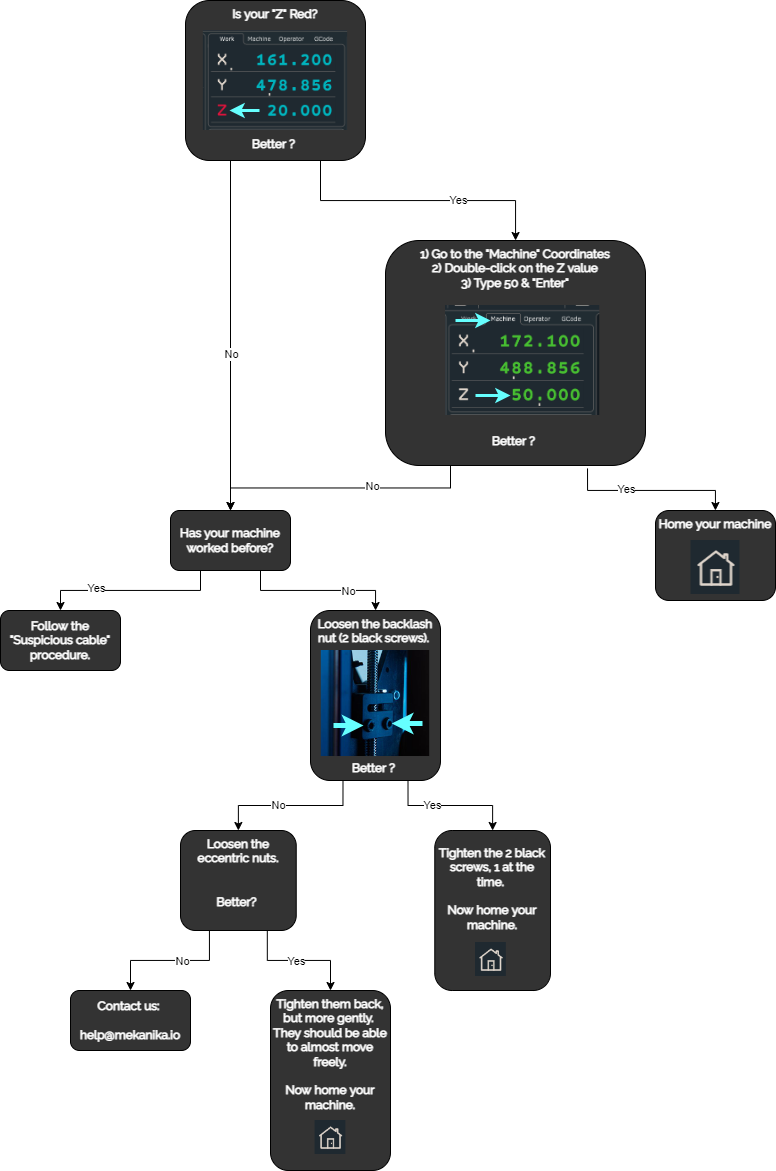

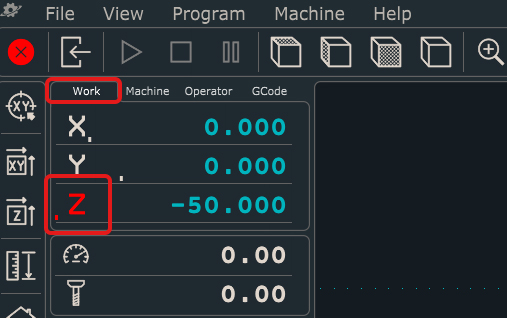

In the "WORK" coordinates (blue coordinates), is the "Z" letter displayed in red?

This would mean the computer thinks it has reached its limit (and therefore doesn't want to go any further), even if it is not true.

We need to tell the computer it is not at its limit, so it can home again and find its true position.

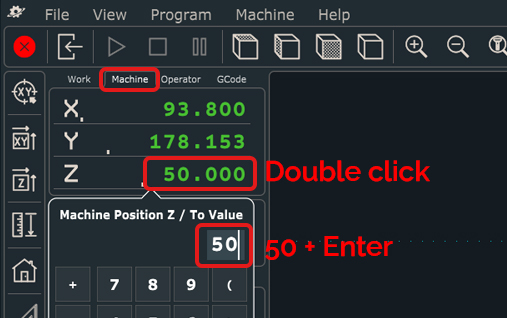

- Go to the Machine coordinates tab (green coordinates).

- Double-Click on the green number behind the Z.

- Enter the value 50, and then press Enter.

▶ Is the Z able to go up now ? (make sure your spindle is not already at the maximum height when trying)

- Home the machine so it can get its real Z coordinates and not the temporary ones we gave it.

- Check if everything works as intended with the Z axis (if not start the guide again)

- The problem should be solved

This means the coordinates' system are set correctly, so the problem comes from somewhere else than the software.

▶ Has your machine worked normally before? (The problem is new?)

This means something happened to the machine, probably hardware as the coordinates are set correctly. It could be a faulty cable (it might have been damaged internally).

▶ Please follow this "Suspicious Cable Procedure" to identify it.

And then contact our support team to tell them the results of the procedure.

There might be something during the assembly that was set incorrectly and prevents the Z from going up.

On Pro and Fab: please contact our support to identify the origin.

On Evo: Try to loosen the anti-backlash nut's fixation screws (2 black screws) fixing it.

▶ Can you now move the Z axis upwards with the nut loosened?

It was probably just tightened too strongly and was blocking the lead screw's rotation.

- Tighten them again by alternating one screw and the other.

- Regularly check that you can still move the Z axis up and down without any resistance.

- Stop tightening when the nut feels tight, but the Z axis can still go upwards.

- Home the machine

- The problem should be solved

This means the lead screw is not the one being blocked, it might be the wheels applying too much pressure on the rails.

- Loosen the eccentric nuts of the 4 wheels on the Z-axis.

- If you can move the Z up when they are loose: then tighten them back gently, while checking if you can still move up.

- Home the machine

- The problem should be solved

▶ If nothing changes with this last troubleshooting step, we'll need to investigate the origin with you.

Please contact our support team, and explain them all the steps you followed, so we can help you as fast as possible!