How to split a milling job in two without loosing coordinates

You plan a very long milling job, for which you'll need to shut down your machine to continue the job later? That's possible!

This is a guide for more advanced users: when done carefully, it can be easy to do. But if you don't get prepared well or don't understand completely how the machine reacts to commands yet, it is very easy to break an end mill, ruin your stock/parts or even damage the machine... So be careful.

If you are a beginner or if your program stopped unintentionally, we recommend following this more detailed tutorial that will explain everything about the function to resume the job.

1. Coordinates

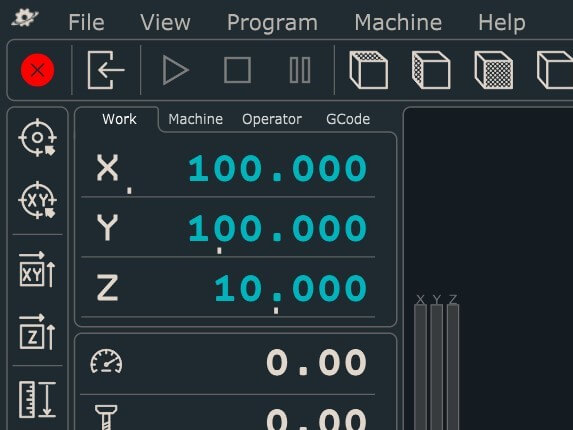

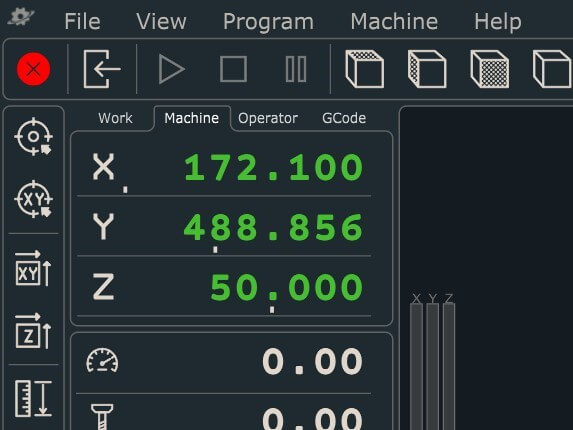

First of all before starting the job (and after you've done a Home and a Square), take note of the Machine Coordinates at which you place the Work coordinates X0 Y0 Z0. (you'll need them in case of problem).

2. End of first milling session

To end your first milling session, press pause on the keypad.

- Stop the spindle.

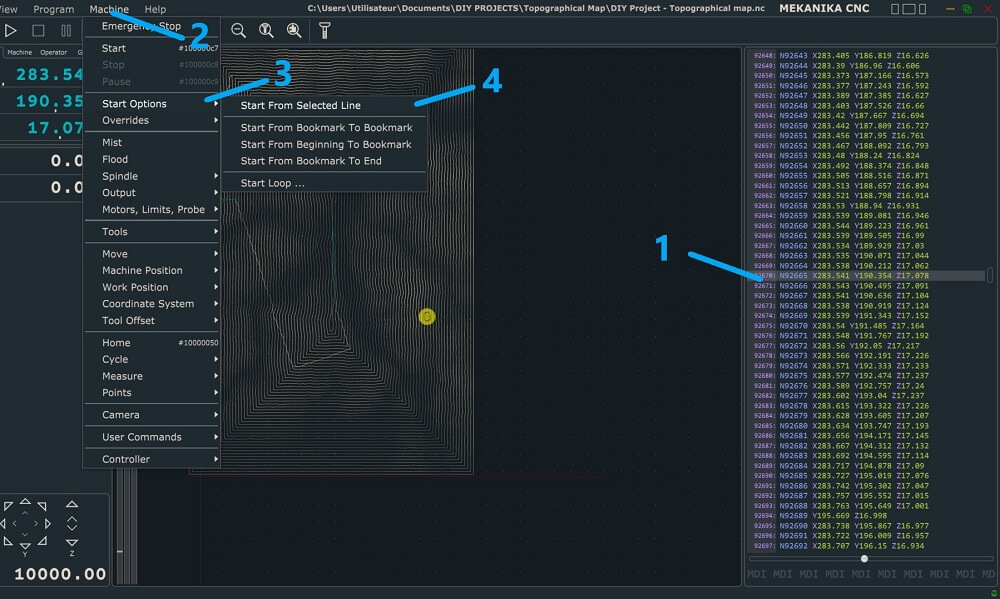

- Write down the G-code line number on which you paused.

- Write down the XYZ Work and XYZ Machine coordinates at which you stopped the job.

3. Start of the second milling session

When you are ready to start again the milling session:

- Turn on the machine and start by checking that the "work" and "machine" coordinates are still as you left them. (if nothing happened to the machine they should'nt have moved). If they moved, do a new Home and Square, setup the Work X0Y0Z0 at the same Machine Coordinates you took not of. Then send the machine to the coordinates where you stoped the program (be careful that nothing is on the way of the tool).

- Start the spindle.

- Follow this procedure to restart the milling at the given line:

- Select the correct line in the right panel!

- Click on Machine > Start Options > Start from selected line

KEEP AN HAND ON THE EMERGENCY STOP in case you did something wrong (wrong line, wrong coordinates... anything. Because the machine will start moving right away and quickly.- If you did everything right, the milling will start from the place you stopped.

- Select the correct line in the right panel!

This procedure and menu option can also be used to catch back a milling that was stopped due to a crash, or a power outage for example, but be very careful with it once again, as the line selection is very important, and you could damage a lot of things with a mistake.