Tool change

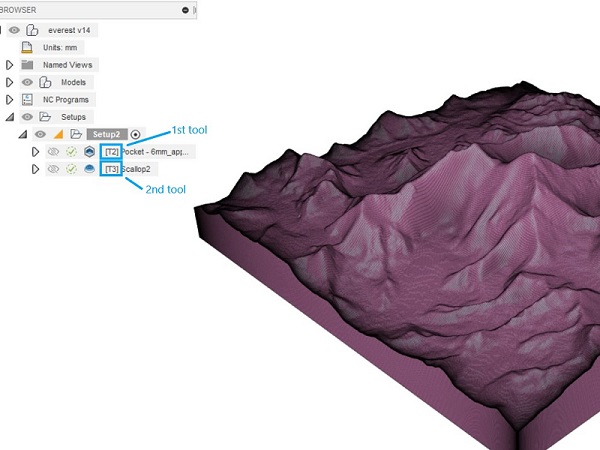

Recognize a multi-tool project

A) CAM

In your CAM environment every milling operation gets an assigned tool. If this tool is different, the software will post that information when generating the Gcode.

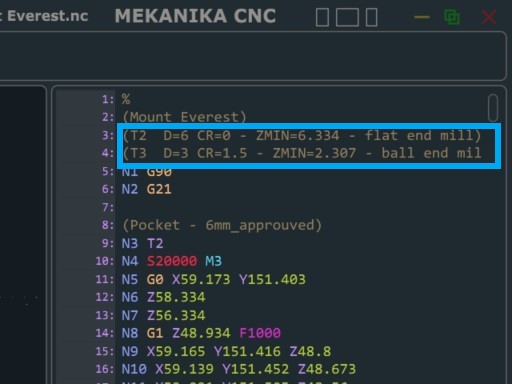

B) Gcode

In the Gcode, the tools are always specified on top.

As soon as you see a Gcode with multiple "T lines" at the beginning, you can be sure a tool change is involved and you also know which tools are needed.

Procedure

Tool change on a MEKANIKA CNC machine is very easy and only takes a couple of seconds, actually you have almost nothing to do.

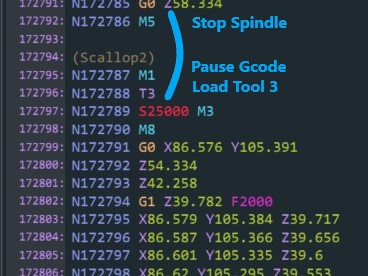

0) Once you started the milling, the machine will perform all the operations where the first tool is used.

1) When you need to change tools, it will pause the Gcode automatically and place the end mill above the stock. (If you have a DI/VFD spindle it will also stop the spindle.)

2) You can now change the end mill and probe the new one as you would do to start a new milling.

3) Now place the end mill more or less where it is supposed to resume the Gcode.

WARNING! Once you resume the milling, your cnc will go in a straight line to the position it is supposed to be starting from. We thus recommend to manually place your spindle as close as possible to that position.

4) Start your spindle (if it's a DI/VFD spindle the CNC will do it for you).

5) Press play, and you're back in the game.