Tool change procedure on a Mekanika CNC

Some milling jobs use multiple end mills. This requires a tool change operation and here's how to do it on a Mekanika CNC machine.

▶ How to recognize/prepare a multi-tool project

1. CAM

In your CAM environment every milling operation gets an assigned tool. If there are different tools used, the software will post that information when generating the G-code.

Note: if all the operations are using the same tool, no tool change will be applied to the code and the machine will continue to the next operation automatically.

2. G-Code

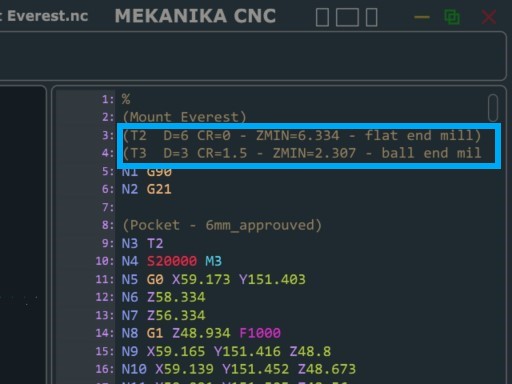

In the G-code, all the tools used in the whole project are specified in the information at the very begining of the file.

In the G-code, a tool is named by a T followed by the tool's number.

See our article about the basics of G-code to learn more.

As soon as you see a Gcode with multiple "T lines" at the beginning, you can be sure a tool change is involved and you also know which tools are needed by reading their description.

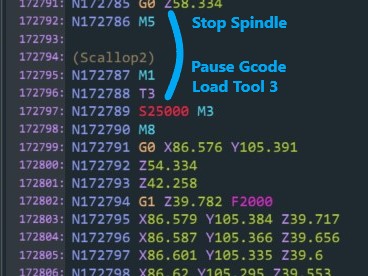

If we search in the code, we can find the moment(s) it requires a tool change by spotting the M5 (stop the spindle), M1 (pause the job) and Tx (indicates the new tool used).

▶ Tool change procedure on Mekanika machines

0. Once you started the milling with the first tool, the machine will perform all the operations where this tool is used until it reaches the tool change steps described above.

1. When it reaches that point, it will automatically put the Machine (and G-code) in pause, and lift the end mill above the stock.

If you have a DI/VFD spindle it will also stop the spindle rotation. Otherwise you can stop your manual spindle.

2. In that state, you can move the machine freely with the arrows, without loosing the coordinates. Bring it closer to you so you can easily remove the previous end mill.

Place the new one in the spindle, but

3. WARNING! Once you resume the milling, your cnc will go in a straight line above the position it is supposed to be starting again from. We thus recommend to lift the spindle up as much as possible when you have finished fixing and probing the new tool to avoid any collisions with the stock or clamps.

4. If your spindle is activated manually don't forget to launch it again before continuing. (If it's a DI/VFD spindle the CNC will do it automatically when resuming the job).

5. Press play to tell the machine when you are ready to resume the job with the new tool. It will go above the new tool's operation start point, and begin its toolpath.